How to Use the DPLSY Instruction in Mitsubishi PLC: A Comprehensive Guide

In industrial automation systems, precise control of servo

motors is critical for various applications, including motion control

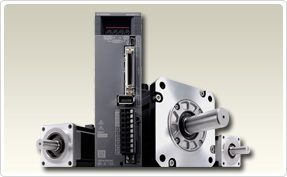

and positioning systems. Mitsubishi Electric, known for its

high-quality automation solutions, offers a robust range of servo products,

including the Mitsubishi Servo Drive and MELSERVO series,

designed for such applications. One important instruction for controlling pulse

outputs in these systems is the DPLSY instruction. This instruction,

used in Mitsubishi PLCs, enables the output of 32-bit pulse trains,

which is essential for precise motion control in servo systems.

Let’s take a deeper look at how to effectively use the DPLSY

instruction in Mitsubishi PLCs, focusing on its application with Mitsubishi

Servo Pulse Type systems, and understanding the relationship with Mitsubishi

DDRVI instructions.

What is the DPLSY Instruction?

The DPLSY (Pulse Output) instruction in Mitsubishi

PLCs is used to output a 32-bit pulse train from a specified device for

a set number of pulses, which is determined by a positioning address.

This instruction is essential when controlling servo motors in

applications where accurate and adjustable pulse generation is needed. The

frequency and number of pulses can be dynamically controlled, making this a

versatile instruction for Mitsubishi Servo Drive systems.

Basic Syntax:

DPLSY d, s, n

- d

(output device): The device where the pulse output is sent, for

example, a servo motor or a related actuator (e.g., Y0 for Axis 1).

- s

(speed): The pulse output speed, specified in a unit such as K1000

(frequency of the pulse).

- n

(positioning address): The number of pulses to output. If n is

set to 0, the pulse output will be unlimited.

Step-by-Step Guide to Using DPLSY Instruction

Step 1: Unlimited Pulse Output

In some applications, there might be a need for continuous,

unlimited pulse output. This can be easily achieved by setting the positioning

address (operand n) to 0. With this setting, the PLC will keep

outputting pulses indefinitely, controlled by the specified frequency.

Example:

DPLSY K1, K1000, K0

- K1:

The output device, in this case, Axis 1 (Y0).

- K1000:

Pulse output frequency, which could be something like 1000 pulses per

second.

- K0:

Unlimited pulse output (no limit on the number of pulses to be output).

This configuration results in Mitsubishi Servo Pulse Type

output, where the servo motor will continue to rotate at the set pulse

frequency until another command halts the output.

Step 2: Pulse Output with Defined Number of Pulses

In many motion control systems, you may need to output a

specific number of pulses for a given action. This is done by setting a value

for the positioning address (n). For example, if you want the servo

motor to complete a specific movement by outputting a set number of pulses, you

can specify the total number of pulses in the positioning address.

Example:

DPLSY K1, K1000, K500

- K1:

The output device, Axis 1 (Y0), connected to the servo.

- K1000:

Pulse output frequency.

- K500:

The number of pulses to output, in this case, 500 pulses.

In this scenario, the servo motor will output exactly 500

pulses at the frequency of K1000, controlling the motion precisely.

Step 3: Using Variable Frequency and Positioning Address

One of the key features of the DPLSY instruction is

its flexibility, allowing you to dynamically change the pulse output

frequency and number of pulses using D registers. This

flexibility is especially useful in real-time systems where pulse frequencies

or motion parameters need to change based on the operational conditions.

For example, you could define the pulse frequency in a D

register and pass it to the DPLSY instruction at runtime.

Example:

DPLSY K1, D100, D200

- K1:

Axis 1 (Y0) for the servo motor.

- D100:

A D register containing the pulse output frequency.

- D200:

A D register specifying the number of pulses to be output.

With this configuration, the PLC will use the pulse

frequency and the number of pulses defined in the D registers at the

time of execution. This makes the pulse generation adaptable to varying

conditions in your system.

Integration with Mitsubishi Servo Drive and DDRVI

Instruction

The DPLSY instruction works seamlessly with

Mitsubishi's Servo Drive systems, such as the MELSERVO series, to

control precise movements. When working with Mitsubishi DDRVI instructions

(Direct Digital Register Variable Instruction), you can integrate position

feedback and control adjustments in real-time, ensuring the servo motor reaches

the desired position accurately.

For example, you might use the DDRVI instruction to

read feedback from a connected Mitsubishi Servo Drive and adjust the

pulse frequency or positioning parameters dynamically, based on the actual

position of the servo. This integration ensures that the system can respond to

changing conditions and maintain precise control over the motion.

Conclusion

The DPLSY instruction is a powerful tool for pulse

output in Mitsubishi PLC systems, especially when controlling Mitsubishi

Servo Drives in motion control and positioning systems.

Whether you are using it for unlimited pulse output or precise positioning with

a defined number of pulses, this instruction provides the flexibility and

precision needed for various industrial applications. By combining it with Mitsubishi

DDRVI instructions, Mitsubishi Servo Pulse Type, and MELSERVO

drives, you can achieve highly reliable and dynamic control over servo motor

movements.

Watch Our Video Tutorial on the DPLSY Instruction!

For those who prefer a more hands-on approach, we also have a detailed video tutorial available that walks you through the use of the DPLSY instruction in Mitsubishi PLCs. This tutorial covers everything from the basics of pulse output to advanced techniques like using variable frequency and positioning addresses, all while demonstrating the integration with Mitsubishi Servo Drives and the MITSUBISHI DDRVI instruction.

If you found this blog helpful, be sure to check out the video for a more visual and interactive explanation.

Don’t forget to like the blog if you found the information useful, and feel free to share it with your colleagues or anyone interested in mastering Mitsubishi PLC programming. Your support helps us create more valuable content for the automation community!

Happy learning, and stay tuned for more tutorials!

IT Solutions Provider

ReplyDelete